Foundry

Saint-Gobain Performance Ceramics & Refractories (PCR) delivers cutting-edge refractory solutions tailored to the demanding requirements of both ferrous and non-ferrous foundries. Backed by decades of industry expertise, NORTON® product portfolio—including for example NORVIBE™ dry vibrated monolithics, NORCAST™ castables, and NORRAM™ ramming mixes and more.

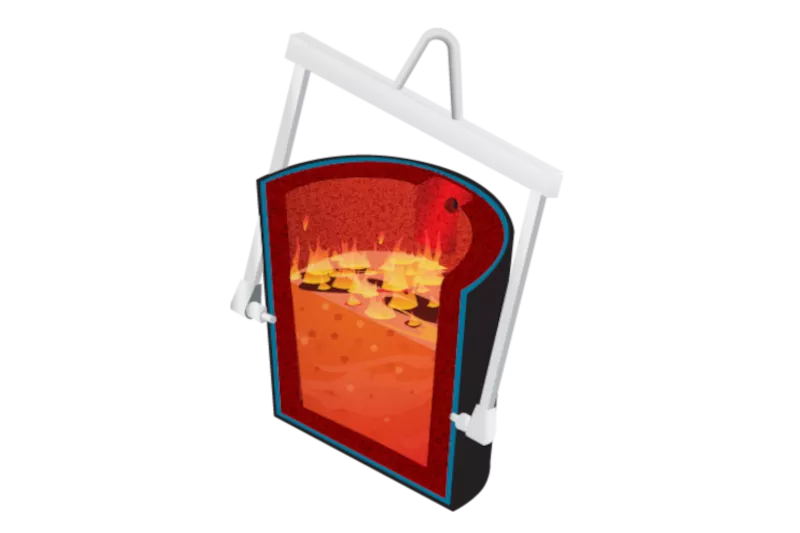

This product range offers reliable performance across a wide range of high-temperature applications such as coreless induction furnaces, ladles and pouring furnaces.

Engineered to withstand extreme operating conditions, our refractory materials provide outstanding corrosion resistance, mechanical integrity, and long service life, supporting greater process stability and metallurgical purity.

Beyond materials, Saint-Gobain PCR provides a comprehensive service offering, including refractory design, installation and repair, supervision, and performance auditing. Our expert teams collaborate closely with customers to optimize furnace performance, reduce energy consumption, minimize emissions, and support sustainable manufacturing practices, including waste recycling and EHS-compliant solutions.

Solution By Equipment

Click on your equipment to find more:

- Coreless Induction Furnace

- Inductor

- Ladle & Other

- Pouring Furnace

- Cupola

Ladle & Other

FAQ

Is it possible to quickly and easily install a castable while maintaining product performance and service life?

The NORFLOW® range of self-flowing castables can be installed without the use of vibration tools or other vibration assistance. Compared to conventional castables, NORFLOW® offers excellent strength, homogeneity and erosion resistance while maintaining lower water content during casting.

Many melt shops operate with a single ladle - how quickly can a ladle be brought back into service following relining with refractory?

The NORFAST® product range has been specifically designed to address this issue. NORFAST® employs a special bonding system which enables quicker drying and sintering, ideal for rapidly bringing equipment back into service without impacting overall service life.