Specialty Ceramics Solutions

High-performance advanced ceramics for extreme conditions

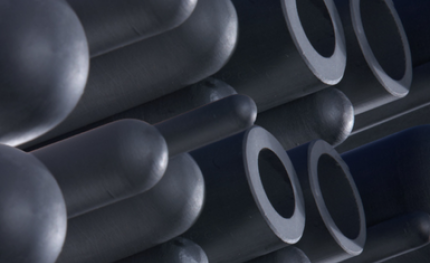

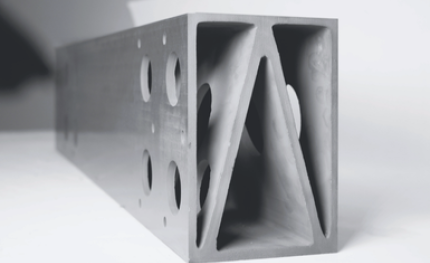

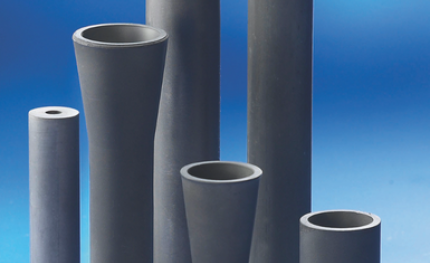

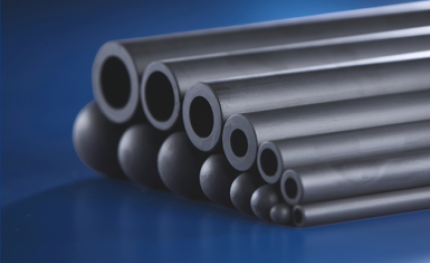

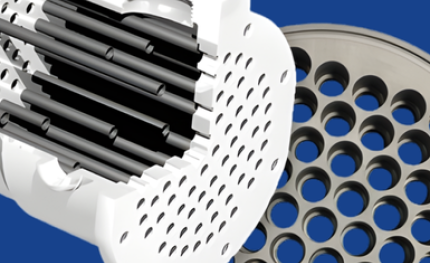

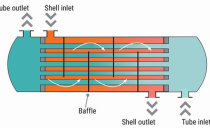

Saint-Gobain Performance Ceramics & Refractories offers advanced specialty ceramics products, consisting of silicon carbide, silicon nitride, Alumina and Boron Carbide materials, designed to perform reliably in the harshest conditions. These engineered solutions provide exceptional thermal stability, corrosion resistance, and mechanical strength, making them ideal for high-temperature reactors, chemically aggressive processes, precision metrology, mechanical seals, thermocouple protection & gas sensors, labware operations, and semiconductor manufacturing equipment. Focused on durability and efficiency, Saint-Gobain’s solutions help critical industries improve reliability, minimize maintenance, and optimize operational performance.

Engineered Materials

Saint-Gobain Refractories' range of specialty ceramics includes:

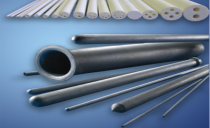

- Advancer®, N-Durance®, Cryston(R), Refrax 20E – Lightweight, oxidation-resistant Silicon nitride bonded silicon carbide material engineered for high-performance thermocouple protection tubes, precision metrology, process reactor lining, and microwave absorption.

- Alundum® – Fused alumina delivering superior corrosion resistance and mechanical durability, making it well-suited to laboratory equipment and refractory lining for furnaces.

- Crystar® RB (Silit®) – Reaction-bonded silicon carbide designed for thermal and chemical stability in precision metrology and high temperature process reactor tubes

- Hexoloy® – Sintered alpha silicon carbide valued for extreme hardness, wear resistance, exceptional corrosion resistance and mechanical strength in high & low temperature processes, equipment that are often subject to thermal & pressure gradients, aggressive chemicals, and high load

- Magnorite® – Magnesium oxide ceramic with high thermal and electrical resistance, ideal for insulation of thermocouple wires.

- Noralide® – Hot-pressed silicon nitride featuring high strength and fracture toughness, developed for application in nuclear reactor coolant pump seals, aerospace equipment.

- Norbide® – Hot-pressed boron carbide used for demanding wear-resistant nozzles and other custom parts, and neutron-absorbing applications in nuclear reactors.

Applications of Advanced Ceramics

We design specialty ceramics products for use in demanding industrial settings. Each solution is matched to a specific application, offering the thermal stability, mechanical strength, or chemical resistance required to improve reliability and maintain performance under stress.

Shaping a Cleaner Future with Advanced Ceramics

Discover how Saint-Gobain Performance Ceramics & Refractories is driving innovation for a more sustainable world.

From high-performance components for nuclear and solar energy to breakthrough materials enabling industrial decarbonization, our advanced ceramics and refractories are helping industries transition to cleaner, more efficient processes.

Speak to an Expert

Contact our engineering team for personalized guidance on specialty ceramics and silicon carbide products tailored to your operational requirements.