Coating Application Service for Coreless Induction Furnaces

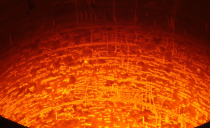

Saint-Gobain Performance Ceramics & Refractories offers an exclusive refractory coating application service for coreless induction furnaces. Our dedicated team of specialized engineers performs on-site applications, ensuring optimal refractory coating precision and enhancing the performance of your steel melting operations. By partnering with us, you gain access to our unparalleled expertise and the superior performance of HeatKing™ Neutral Ramming Mass, an unmatched value proposition in the induction furnace industry.

- Scrap melting

- Direct Reduced Iron (DRI) Melting

- Stainless Steel Production

- Special Alloy Steel Production

- Small Foundries

Direct Reduced Iron (DRI) Melting

India and its neighboring countries utilize a unique method to produce direct reduced iron (DRI) by reducing iron ore with coal in rotary kilns. This process is widely adopted in the Indian subcontinent due to the abundant availability of iron ore and coal, making steel production highly cost-effective in this region.

However, melting DRI in induction furnaces presents several challenges, such as corrosive slag and higher melting temperatures. These challenges demand the use of high-performance refractories. HeatKing™ solutions provide ideal lining solutions for DRI melting, offering significant benefits such as:

- Increased productivity

- Reduced energy consumption

- Enhanced safety

- The Hot Heal feature, which minimizes scrap consumption

Experience the efficiency and reliability of HeatKing™ solutions to overcome the challenges of DRI melting and maximize your production capabilities.

Stainless Steel Production

Globally, stainless steel production is on the rise due to its superior durability compared to regular steel. Stainless steel is typically melted by remelting stainless steel scrap or by creating steel with additions of ferrochrome in an induction furnace. This process generates basic slag and highly corrosive manganese, which can react with traditional refractory linings and reduce their performance.

HeatKing™ products offer ideal lining solutions designed to withstand basic slags and corrosive elements. Our solutions ensure greater recovery of expensive alloying elements in the input material, enhancing the efficiency and cost-effectiveness of stainless steel production.

The demand for special alloy steels is growing across various applications. Recent advancements in melting and refining processes now enable the production of high-quality alloy steel in induction furnaces, comparable to Electric Arc Furnaces.

Producing high-quality alloy steel in an induction furnace greatly benefits from high-performance refractory linings, which enhance alloy recovery and minimize refractory material inclusions in the ingots. HeatKing™ solutions are designed to meet the highest quality standards, ensuring minimal refractory inclusions and maximum alloy recovery in ingot production.

Induction furnaces are widely used in small foundries to produce special steel castings, with furnace capacities typically ranging from 50 kg to 3000 kg of metal. Market demand is driving the need for refractory linings capable of handling both acidic and basic slags.

HeatKing™ solutions offer a range of products designed for these applications, ensuring higher alloy recovery and superior performance.