Key Benefits of Radiant Tube Inserts

Both the SpyroCor® and NOxBuster® radiant tube inserts can be used together to establish temperature uniformity. Individually, their advantages include:

- Retrofitted with radiant tubes that have already been created

- Used to achieve 15% energy savings

- Have the capability to lower emissions

- Includes thin-wall silicon carbide to ensure thermal performance and heat transfers occur at an excellent rate

- Decreased flame temperature and NOx emissions through patented design

- Utilized to deliver energy savings through taking away hot-spots

Material Description and Applications

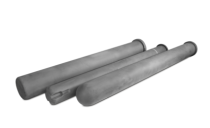

A SpyroCor® radiant tube insert can be used within a radiant tube to enhance the levels of heat the furnace chamber is able to receive from it. Additionally, it can serve to boost the radiant tube’s efficiency, having the capability to better its throughput by 6% at maximum.

The NOxBuster® radiant tube insert is also used within a radiant tube. However, what makes it stand out is its ability to lower NOx emissions by 50%. Here at Saint-Gobain Refractories, our goal is to help reduce the harm caused by pollution, having lowered our own carbon emissions by 34% in 2023. We are dedicated to creating products that will have less of an effect on the environment.

Silicon carbide is a material used in each of these types of radiant tube inserts. The capabilities of this material lend nicely to radiant tube inserts thanks to its thermal shock and heat resistance. When used within a radiant tube insert it can improve the productivity of its heat transfers and the furnace’s performance.

A radiant tube insert is usually found within a radiant tube furnace, acting as an upgrade for this device to improve its combustion capabilities. If applied to a radiant tube, a radiant tube insert can be used for glass manufacturing and metal heat treatment procedures. Our own SpyroCor® radiant tube inserts can be applied to the following types of radiant tubes:

Want to Know More?

Let us supply you with robust equipment to ensure your heating apparatus functions as productively as possible. You can rely on our radiant tube inserts, as well as our extensive experience, to uncover a product that will fit with your work.

FAQ

What sort of materials are used to create radiant tube inserts?

Silicon carbide tends to be used in radiant tube inserts, because of its extensive thermal stability and ability to withstand oxidation, however there are other materials that can be used as well. These include aluminum, steel, ceramics, and alloys.

Are there any temperature limits for radiant tube inserts?

The temperature limits of radiant tube inserts depend on the materials they are made out of. For instance, a radiant tube insert made out of silicon carbide could be used in temperatures that meet 1,250°c. But a radiant tube insert formed from cast steel is different and can only resist temperatures reaching 1,100°c. SpyroCor® radiant tube inserts can be utilized till temperatures hit 1,380°c.

Are there any environmental benefits to using radiant tube inserts from Saint-Gobain Refractories?

The SpyroCor® radiant tube insert has a patented twist fin design. Its design helps it to take in heat and move it back to the furnace. By utilizing this design, the amount of carbon generated and energy used can be lowered by around 5-15%. Moreover, the NOxBuster® radiant tube insert can be used to lower NOx emissions by 50% at most.

Uncover More About The Products We Make For Non-Ferrous Metallurgy Procedures

Documents

Related Content

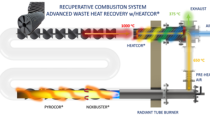

Total Burner Solution for Energy Efficiency and Carbon Reduction

Discover Saint-Gobain Performance Ceramics & Refractories’ extensive range of total burner solutions for industrial heating applications.

Single Ended Radiant Tubes

Discover Saint-Gobain Performance Ceramics & Refractories’ extensive range of solutions for high temperature heat treatment applications.

U-TUBE

Discover Saint-Gobain Performance Ceramics & Refractories’ solutions for high temperature heat treatment applications in U-tube combustion systems.

W-TUBE

Discover Saint-Gobain Performance Ceramics & Refractories’ solutions for high temperature heat treatment applications in W-tube combustion systems.

Radiant Refractory Tubes: Properties & Applications

Saint-Gobain radiant refractory tubes can output as much as twice the energy of standard alloy radiant elements into furnace environments.

Direct & Indirect Heating Burner Solutions from Saint-Gobain

As producers look for ways to push their industrial heating processes to higher efficiencies and outputs, they are faced with new challenges.

A New Spin on Zinc Melting Furnaces

Saint-Gobain close the technology gap with the introduction of their enhanced SpyroCor® flame diffuser insert for immersion tube furnaces.

Related Products

Ceramic Radiant Tube

Discover Saint-Gobain Performance Ceramics & Refractories’ extensive range of solutions for high temperature heat treatment applications.

HeatCor and Silit Recuperators

Discover Saint-Gobain Performance Ceramics & Refractories’ range of recuperators for integration into burner systems.

PyroCor and Silit Flame Tubes

Discover Saint-Gobain Performance Ceramics & Refractories’ range of flame tubes and diffusers – ideal for guiding the flow of combustion.