Filtration

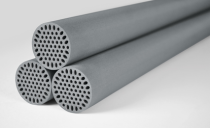

Saint-Gobain Performance Ceramics & Refractories have been providing unique and high added value silicon carbide-based solutions for decades, including the first-to-market recrystallized silicon carbide (R-SiC) product. This outstanding ceramic forms the basis of our Crystar® filtration technology.

Crystar® FT is designed for liquid and air purity, security, and sustainability. The demands of filtration have changed dramatically over the years, as a growing global population forces industries to adopt more demanding processing capabilities to satisfy the needs of global sustainability efforts.

Saint-Gobain designs, manufactures and distributes materials and solutions which are key ingredients in the well being of each of us and the future of all. They provide comfort, performance and safety while addressing the challenges of sustainable construction, resource efficiency and climate change.

With Crystar® FT membranes and filters, Saint-Gobain is committed to improving the sustainability of sectors as diverse as water/wastewater, industrial processes & life sciences, and recreational water, with new and innovative products.

We aim to make sustainability a driving force for every liquid filtration and air purification sector. Crystar® FT technology provides microfiltration of leading efficiency, with consistent retention, excellent filtrate quality at high fluxes, and operation with low consumption of energy, water and chemicals.

Beer Clarification

Beer clarification is a crucial yet difficult stage of the brewing process. It is used to reduce haze in the finished product which may be caused by low temperature reactions between tannins and proteins, as well as by biological particulates such as lactic bacteria and yeast. The challenge is to efficient clarify and stabilize the beer while preserving its taste and consistency.

Crystar® FT is certified for food contact under the European Regulations No 1935/2004 and deemed acceptable for food processing by the US FDA.

Benefits of Crystar® Filtration