Foundry

Saint-Gobain Performance Ceramics & Refractories (PCR) delivers cutting-edge refractory solutions tailored to the demanding requirements of both ferrous and non-ferrous foundries. Backed by decades of industry expertise, NORTON® product portfolio—including for example NORVIBE™ dry vibrated monolithics, NORCAST™ castables, and NORRAM™ ramming mixes and more.

This product range offers reliable performance across a wide range of high-temperature applications such as coreless induction furnaces, ladles and pouring furnaces.

Engineered to withstand extreme operating conditions, our refractory materials provide outstanding corrosion resistance, mechanical integrity, and long service life, supporting greater process stability and metallurgical purity.

Beyond materials, Saint-Gobain PCR provides a comprehensive service offering, including refractory design, installation and repair, supervision, and performance auditing. Our expert teams collaborate closely with customers to optimize furnace performance, reduce energy consumption, minimize emissions, and support sustainable manufacturing practices, including waste recycling and EHS-compliant solutions.

Solution By Equipment

Click on your equipment to find more:

- Coreless Induction Furnace

- Inductor

- Ladle & Other

- Pouring Furnace

- Cupola

Coreless Induction Furnace

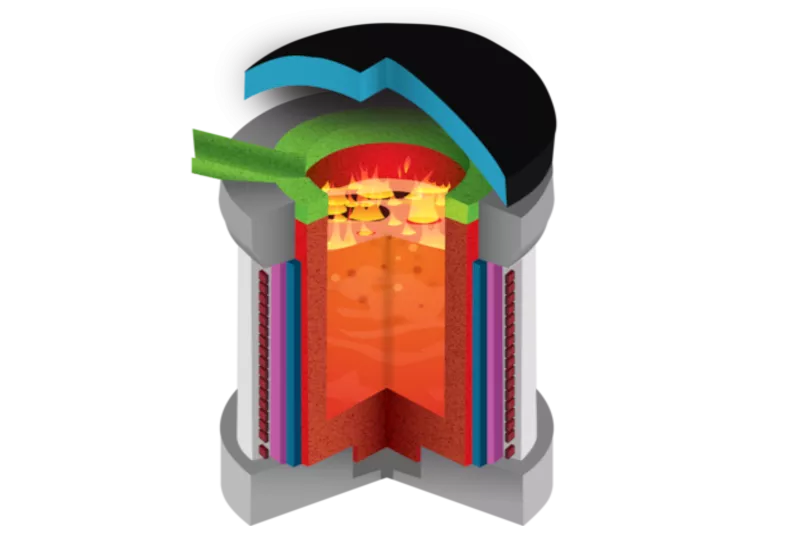

Coreless induction furnaces are widely used in steel and alloy production due to their flexibility and handling capabilities.

Saint-Gobain Performance Ceramics & Refractories provides products specifically developed to enhance key factors impacting end product quality. High grade refractories for coil lining, working lining, topping and spout areas are also available.

The entire coreless induction furnace product range has been developed to help improve the energy balance in production, reducing overall costs in line with local market requirements. For example, customers in India have seen notable improvements by employing the HeatKing™ product.

Saint-Gobain Performance Ceramics & Refractories’ innovative refractory lining products can reduce CO2 emissions during melting operations by 5% versus traditional silica based ramming mixes – facilitating a significant reduction in customers’ carbon footprints.

FAQ

What is the best mix for optimized copper melting performance?

The NORVIBE™ range of products is well suited for use in the working lining of a copper-melting coreless induction furnace.

The NORVIBE™ A 122 mix is a popular and proven choice for copper melting in many international markets. It offers excellent results with low metal infiltration ensuring performance, reliability and extended furnace campaign life.

What type of product is suitable for coil protection?

The NORCOIL™ range has been designed to enhanced performance during lining installation (for example, ease of installation, setting time, and drying) and melting operations conditions (for example, furnace tilting, frequency and vibration changes). NORCOIL™ A 337, A 339 and A 340 are particularly popular with OEM and foundry customers operating coreless induction furnaces.

Which products are suitable for the side wall lining/working lining for steel melting in a coreless induction furnace?

The NORVIBE™ range of products is well suited for use in the working lining of a steel-melting coreless induction furnace.

Solutions such as NORVIBE™ A 1248 LG and NORVIBE™ A 1251 (HeatKing™) have been specifically designed to replace silica mixes in steel melting applications.

These solutions are EHS-friendly, leading to energy savings and significant increases in furnace campaign life. A range of mixes containing magnesia and spinel is also available for use with higher alloyed steels.