Sustainable Mining and Mineral Processing

Sustainable mining is a challenging prospect, given the mineral processing industry is inherently focused on extracting limited resources from the ground. The direct environmental impact of valuable mineral processing operations is hard to quantify. But sustainable development of more effective tools in mineral processing plants can add enormous value to the entire extractive metallurgy chain. Saint-Gobain Performance Ceramics & Refractories, with 50+ years of experience in the mining industry, can provide unique solutions that enhance your plant's commerciality and underlie key environmental and social responsibility goals.

Abrasion Resistant Solutions for More Sustainable Mining Operations

Mining and mineral processing involve an array of harsh processes, like crushing and grinding, which take a severe toll on processing equipment. Pulverizing and conveying high volumes of solids with varying particle sizes causes unavoidable wear and tear. Ongoing maintenance is required to avoid component failure due to abrasion and erosion, but most equipment has a limited lifecycle, even with diligent repairs.

Extending the service life of critical components is a key part of sustainable mining and mineral processing operations. At Saint-Gobain, we have developed a range of wear-resistant linings designed to reduce the extra expenses associated with equipment repair and replacement while mitigating the resulting downtime. Our linings outperform carbon steel by many orders of magnitude, and our newer silicon carbide (SiC) solutions go further still. Replacing conventional carbon steel chokes and linings with an SiC wear-resistant solution maintains operation continuity for longer periods, significantly reduces material consumption while driving down the risk of leaks and spills.

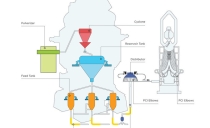

A wide range of equipment can be lined or retrofitted using our alumina and SiC wear-resistant technology (WRT) materials, including:

- AG-SAG feed chutes

- Barge or ship loading chutes and hoppers

- Rail car loading chutes and hoppers

- Concentrate to processing plants

- Conveyors to storage silos

- Crushing and sizing equipment

- Cyclone separation equipment

- Dewatering fines to storage tanks

- Mag separators

- Piping to filter presses

- Raw material handling tools

- Rotary car dumpers

- Separation stackers and reclaimers

- Storage silos

- Sump piping suction and discharge

- Table or mechanical feeders

- Tailing lines

- Trommel screen underflow chutes

FAQ

Which wear-resistant ceramic materials can outperform rubber-lined steel and hardened pipe in terms of abrasion and corrosion resistance?

Saint-Gobain Performance Ceramics & Refractories produces many material types able to withstand highly abrasive and corrosive environments. These include:

- Durafrax® - fine grain, high grade alumina

- Cryston® - high performance nitride-bonded silicon carbide

- Corguard® - ZAC fused cast AZS (a combination of alumina, zirconia and silica)

- Norfrax® - fine grain reaction bonded silicon carbide

- Hexoloy® - pressureless sintered silicon carbide

- Hammerfrax™ - patented high performance reaction bonded silicon carbide

- Refrax® - nitride bonded silicon carbide

Will Saint-Gobain Performance Ceramics & Refractories’ ceramics ensure improved value and performance versus a customer’s existing materials?

Yes. Even if a customer is already employing ceramic solutions, Saint-Gobain Performance Ceramics & Refractories’ experienced engineers can likely improve the service life of the existing system by introducing stronger, precisely engineered materials.

Lining systems from Saint-Gobain ensure tighter tolerances than traditional refractory bricks, resulting in shorter installation times with fewer field adjustments required.

This material quality, coupled with Saint-Gobain Performance Ceramics & Refractories’ application experience and strong focus on R&D enables the provision of custom engineered solutions that provide consistently better value over equipment service lives.

Related Content

Wear Resistant Technologies

Saint-Gobain Performance Ceramics and Refractories have developed a range of wear resistant technologies using alumina oxides (Al2O3 and ZTA) as well as...

Crushing, Pulverizing, and Grinding Components

Discover Saint-Gobain Performance Ceramics & Refractories’ extensive range of cost-effective wear resistance solutions for crushing, pulverizing and...

Separation and Screening Components

Discover Saint-Gobain Performance Ceramics & Refractories’ extensive range of cost-effective wear resistance solutions for separation and screening...