Pigment & Powder

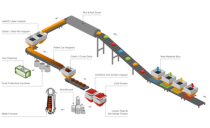

Customized Ceramic Lining Solutions from Ore Handling to Pigment Processing

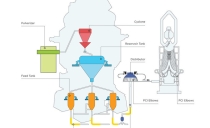

Titanium dioxide (TiO2) producers typically move vast volumes of pigment that abrade and erode equipment. Ongoing maintenance and replacement over the equipment service life can result in extra expense and increased downtime.

Wear-resistant linings from Saint-Gobain Performance Ceramics & Refractories provide unparalleled abrasion and corrosion resistance for TiO2 production and last many times longer than nickel alloys.

Saint-Gobain Performance Ceramics & Refractories is the industry leader in terms of ceramic materials and applications expertise. Lining systems and WRT materials are available for a wide range of processes and equipment, including:

- Pneumatic transport lines

- Valves

- Cyclones

- Pumps

- Feed nozzles

- AZS bricks

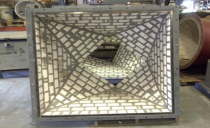

- Quench tower linings

- Volute linings

- Slurry chamber linings

- Pump bushing sleeves

- Flow split valves

- Wear plates

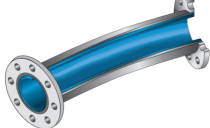

- Elbows

- Micronizers

- Feed tubes

- Hot tickle piping

- Filters

- Calciner linings

- Outlet spools

- Nozzle inserts

- Flue pond fittings

- Sand mills

- Reactor piping

Related Products

Ceramic Cyclone Linings

Discover Saint-Gobain Performance Ceramics & Refractories’ extensive range of ceramic cyclone linings.

Ceramic Chute, Bin and Hopper Linings

Discover Saint-Gobain Performance Ceramics & Refractories’ extensive range of ceramic chute, bin, and hopper linings.

Ceramic Ductwork Linings

Discover Saint-Gobain Performance Ceramics & Refractories’ extensive range of ceramic ductwork linings.

Elbows, Pipes and Fittings Linings

Discover Saint-Gobain Performance Ceramics & Refractories’ extensive range of cost-effective wear resistance solutions – able to extend the service life of...

Related Equipment

Crushing, Pulverizing, and Grinding Components

Discover Saint-Gobain Performance Ceramics & Refractories’ extensive range of cost-effective wear resistance solutions for crushing, pulverizing and...

Separation and Screening Components

Discover Saint-Gobain Performance Ceramics & Refractories’ extensive range of cost-effective wear resistance solutions for separation and screening...

Piping Components

Discover Saint-Gobain Performance Ceramics & Refractories’ extensive range of cost-effective wear resistance solutions for piping components.

Belt Conveyor Components

Discover Saint-Gobain Performance Ceramics & Refractories’ extensive range of cost-effective wear resistance solutions for belt conveyor components.

Sinter Plant

Discover Saint-Gobain Performance Ceramics & Refractories’ extensive range of cost-effective wear resistance solutions for demanding sinter plant...