Electronics & Semiconductors

Fabrication of critical electronic components for the medical, sensor, and consumer electronics markets

Ceramic materials from Saint-Gobain are proven to withstand the extreme demands in the production of electronic ceramics and semiconductor components.

Ceramic materials from Saint-Gobain are engineered for strength, thermal shock resistance, creep resistance, chemical compatibility, dimensional stability and minimal mass, ensuring maximum productivity and longer life.

Engineered ceramics from Saint-Gobain are used in the production of electronic ceramics, including alumina substrates, capacitors, ferrites, titanates, glass, quartz and crystals. Hexoloy® sintered silicon carbide structural ceramics are used in the production of semiconductor components and thin films deposited from silicon carbide sputtering targets.

FAQ

Deposit ultra-pure SiC thin films with Hexoloy® SG silicon carbide sputtering targets?

Hexoloy® SG electrically conductive silicon carbide can be used for DC magnetron SiC sputtering targets.

Silicon carbide thin film coatings are optically transparent, abrasion and corrosion resistant, temperature stable, and have excellent adhesion on a variety of substrates. Applications include optical data and magnetic hard disks, hard protective coatings on flat glass, and conductive or vapor barrier coatings. Excellent thermal conductivity, corrosion resistance and hardness properties promote superior performance and stability in high temperature environments.

Hexoloy® SA sintered silicon carbide outstanding shape and thermal properties for the production of semiconductor components?

Hexoloy® SA sintered silicon carbide is used in the production of components for semiconductor wafer processing such as vacuum chucks, chemical mechanical polishing (CMP) blocks and susceptors. Its thermal expansion match to silicon, high elastic modulus, chemical inertness ensures the economic benefits of maintenance and reuse, and high thermal conductivity for even, rapid heating of the silicon wafer.

Hexoloy® SA silicon carbide is produced by sintering submicron silicon carbide powder. The sintering process results in a self-bonded, fine grain (less than 10μm) SiC product that is extremely hard, lightweight and low in porosity. Outstanding shapeability and resistance to corrosion, erosion, high temperature and thermal shock are other key benefits.

Saint-Gobain refractories and setters for processing electronic ceramics are proven to provide superior performance in high temperature environments?

Electronic ceramics are integral components of numerous devices including computers, wireless communication, automotive and industrial control systems, and digital switches. High performance refractories from Saint-Gobain are proven to withstand the extreme demands in the production of electronic components.

High purity alumina, mullite, zirconia and zirconia-coasted alumina refractories from Saint-Gobain are engineered for strength, thermal shock resistance, creep resistance, chemical compatibility, dimensional stability and minimal mass, ensuring maximum productivity and longer life.

Related Products

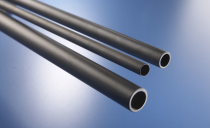

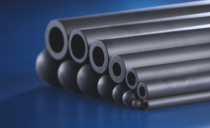

Hexoloy SiC Process Tubes

Discover Saint-Gobain Performance Ceramics & Refractories’ range of process tubes for high temperature processes.

Hexoloy Seal Blanks

Discover Saint-Gobain Performance Ceramics & Refractories’ extensive range of ceramics for mechanical seals.

Related Equipment

Semiconductor Wafer Processing

Hexoloy® SiC ceramics provide mechanical, thermal and chemical stability as wafer carriers, oxidation furnace liners thermocouple protection tubes, and...

Thermal Processing

Advancer®, N-Durance®, and Refrax® 20E Nitride bonded SiC are used to make furnace components with strong resistance to thermal cycling, oxidation, and...