Electronic and Measurement

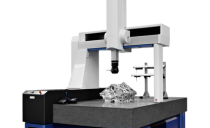

CMM and Positioning Equipment

Saint-Gobain Performance Ceramics & Refractories has been a leading supplier of high quality silicon carbide components for measurement applications.

These include beams for the Z-axis and bridge of CMMs, and plates for the air-bearing stage of motion control equipment.

Electronics & Semiconductors

Electronics & Semiconductors

Description

From pacemakers to pain suppression devices, our ceramics enable fabrication of critical electronic components for the medical, sensor, and consumer ...

High Precision & Accuracy Measurement

High Precision & Accuracy Measurement

Description

Discover Saint-Gobain Performance Ceramics & Refractories’ extensive range of ceramics for metrology – structural components developed in partnership with ...