Ironmaking - Industry

Saint-Gobain Performance Ceramics & Refractories designs and supplies advanced technologies that ensure exceptional results, operational stability and extended equipment service life.

FAQ

How was the Coranit Ceramic Cup developed?

Two sites in Germany - Thyssen's Hamborn and Ruhrort sites - first installed the Ceramic Cup technology in 1984. The first generation of Ceramic Cup was based on chrome-alumina in the form of large precast Monochromcor® blocks, while the second generation was corundum in the form of large precast Mono Coral® blocks. These blocks helped to reduce hearth stresses while addressing issues with chrome VI. The third generation of Ceramic Cup products was developed from pressed SiAlON bonded corundum Coranit bricks and first installed in 1993. This further reduced stresses while offering improved iron erosion resistance. First installed in 2020, Coranit SlagR offers excellent resistance to molten iron and slag and unprecedented hearth lining protection.

What are the benefits of utilizing colloidal silica materials in the lower stack, belly and bosh?

Sialfrax™ 18 Cast demonstrates high mechanical strength at high temperature, while its SiC content ensures high alkali and abrasion resistance.

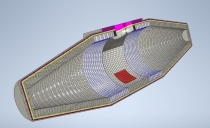

What are the benefits of utilizing the Coranit Ceramic Cup?

The Coranit Ceramic Cup is a popular choice with Saint-Gobain Performance Ceramics & Refractories' customers, boasting over 98 references worldwide and a tendency for customers to reorder due to its 9+ years of service life. The Coranit Ceramic Cup's advanced design and material quality provide significant improvements in service life and operational efficiency – factors that are increasingly important to blast furnace operators. Under typical operating conditions, heat flow at the hearth wall is reduced from 15 kW/m2 to 5 kW/m2. This helps the furnace retain heat, allowing it to be restarted faster after planned or unplanned stoppages and affording the furnace additional protection in case of water leakages. Most notably, this reduction in heat flow also lowers the furnace's carbon footprint.

What are the benefits of working with Saint-Gobain Performance Ceramics & Refractories?

Saint-Gobain Performance Ceramics & Refractories offers a robust combination of continuous development and provision of the highest quality customized refractory product solutions, full design and engineering services, supervision and ongoing support – a complete, reliable and cost-effective service through a furnace's entire service life.

What is the benefit of performing regular hearth repairs?

While regular hearth repairs will not eliminate the eventual need for a full blast furnace reline, they offer significant operational benefits. These include:

- Minimizing Unplanned Downtime: Timely repairs help prevent unexpected failures that could lead to costly production interruptions.

- Extending Campaign Life: By addressing localized wear and damage, repairs can prolong the interval between full relines.

- Improving Safety and Reliability: Maintaining the integrity of the hearth reduces the risk of critical failures and enhances overall furnace stability.

- Cost Efficiency: Smaller, scheduled interventions are generally more economical than emergency shutdowns or premature relining.

In short, regular hearth maintenance is a strategic approach to maximizing furnace uptime and optimizing lifecycle costs.

Which cement is suitable for use in the upper and middle stack?

The low cement Alfrax® 60 Shot shotcrete provides high strength and high erosion resistance in low to medium temperature applications under 1,000°C.

Solution by Application

Blast Furnaces Refractories

Blast Furnaces Refractories

Descubra a gama de soluções refractárias da Saint-Gobain Performance Ceramics & Refractories para aumentar a vida útil dos altos-fornos.

Blast Furnace Repairs

Blast Furnace Repairs

Discover Saint-Gobain Performance Ceramics & Refractories’ shotcrete and castable materials – ideal for interior blast furnace repairs.

Tap Hole Clay

Tap Hole Clay

Discover Saint-Gobain Performance Ceramics & Refractories’ state-of-the art solutions for safe and efficient pig iron production.

Torpedo Car (Torpedo Ladle)

Torpedo Car (Torpedo Ladle)

Discover Saint-Gobain Performance Ceramics & Refractories’ range of engineered refractories – suitable for a wide range of pig iron treatment and transport ...

Iron Wear Resistance

Iron Wear Resistance

Discover Saint-Gobain Performance Ceramics & Refractories’ range of wear resistance solutions for the iron making market.