Technical Ceramics

Advanced Ceramic Processing

Saint-Gobain Performance Ceramics & Refractories’ extensive experience and design expertise ensure that the company’s portfolio of engineered ceramics and refractories are ideally suited for use in the production of high quality technical, advanced and fine ceramics.

FAQ

Can Saint-Gobain Performance Ceramics & Refractories’ kiln furniture withstand high loads at temperatures up to 1350 °C?

Yes. LO-MASS® high strength silicon carbide kiln furniture systems can accommodate the most challenging conditions, including temperatures up to 1350 °C.

The largest insulators are hang-fired and require structures capable of supporting high loads at elevated temperatures. Insulators can be suspended from a frame comprised of advanced silicon carbide support beams and stringer beams (Silit® SK, Crystar® 2000, Advancer® or N-Durance® silicon carbides) and supported by posts made of Carbofrax® oxide bonded Cryston® or AnnaSicon® nitride bonded silicon carbide.

A special kiln car base design is required to resist the high load applied on the posts.

Saint-Gobain Performance Ceramics & Refractories is the industry leader in the design and development of advanced silicon carbide materials and kiln furniture systems.

How do products from Saint-Gobain Performance Ceramics & Refractories perform in terms of thermal shock resistance and high temperature creep resistance?

Alundex®, Alundum®, Alfrax®, AnnaCor®, Mullfrax®, Mulnorite® and AnnaMullit® high alumina-mullite and mullite kiln furniture formulations all offer excellent thermal shock and creep resistance.

An alumina-mullite formulation is an ideal choice for customers looking to minimize thermal shock resistance and creep resistance (sag resistance under load), and in high temperature applications where chemical inertness with the fired product is essential.

Customers looking for very high service temperature capability and chemical inertness are advised to explore the Zirnorite® and Ziral® ranges of zirconia refractories. Saint-Gobain Performance Ceramics & Refractories’ product portfolio also includes calcia, magnesia, and yttria stabilized formulations.

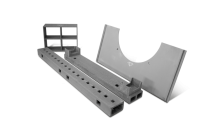

When temperatures allow for the use of advanced silicon carbide components, LO-MASS® kiln furniture systems remain the clear choice for advanced ceramics applications. Systems constructed from advanced silicon carbide (SiC) materials, are thinner, lighter, and significantly stronger than traditional kiln furniture.

Easily combined with other oxide refractory products, Saint-Gobain Performance Ceramics & Refractories’ engineers will design and develop an optimal design solution utilizing the proprietary KilnWorks® software.

Developed to meet the demand for improved energy efficiencies in high temperature applications, LO-MASS® systems from Saint-Gobain Performance Ceramics & Refractories minimize mass while maximizing strength, resulting in greater kiln capacity and reduced firing cycles.

How well do Saint-Gobain Performance Ceramics & Refractories’ ceramics perform in challenging high temperature operating conditions?

Advanced ceramics (also referred to as technical ceramics, engineered ceramics or industrial ceramics) applications utilize a wide range of different and highly specialized ceramic materials; each with unique combinations of mechanical, electrical, thermal and biochemical properties.

Saint-Gobain Performance Ceramics & Refractories offers a variety of furnace refractories and innovative kiln furniture systems capable of responding to the challenging and diverse high temperature operating conditions found in advanced ceramics applications.

Silicon carbide, high purity alumina, high alumina-mullite, mullite and zirconia refractory and kiln furniture products are available to address a wide range of design and product compatibility requirements.

What is the highest purity alumina refractory and furnace lining produced by Saint-Gobain Performance Ceramics & Refractories?

The Alundum® and Alfrax® high purity alumina products contain only trace amounts of oxides which may be reduced by hydrogen at high temperatures. The higher the purity of the material, the lower the dew point in dry hydrogen furnaces. Low tramp oxide content is essential in applications where condensation may disturb catalytic processes or clog filtering.

Related Products

Hexoloy Custom Shapes

Discover Saint-Gobain Performance Ceramics & Refractories’ extensive range of silicon carbide technical ceramics.

Related Content

Technical Ceramics Application

Discover Saint-Gobain Performance Ceramics & Refractories’ comprehensive range of engineered ceramics and refractories – highly suited to producing high...

Systems for Kilns & Furnaces

Discover Saint-Gobain Performance Ceramics & Refractories’ comprehensive range of ceramic products and solutions - designed, developed, and manufactured...