Fertilizer

Unparalleled Refractory Lining Design, Engineering, Products and Services for the Fertilizer Industry

Saint-Gobain Performance Ceramics & Refractories offers unparalleled refractory lining design, engineering, products, and services to the petrochemical industry worldwide.

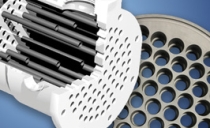

Engineered silicon carbide tubes are used in shell and tube heat exchangers to handle corrosive acids, while non-ferrous refractory designs ensure robust oxidation and chemical resistance, maximizing equipment investment and extending service lives.

FAQ

Are refractories from Saint-Gobain Performance Ceramics & Refractories suitable for use in the production of hydrochloric acid and salt cake?

Sulfate fertilizers are typically processed in Mannheim furnaces. The salt feeder can be lined with mullite bricks (Mullfrax® 202 HF bricks), while the combustion chamber can be lined with Carbofrax® M silicate bonded SiC tiles in the muffle dome in order to ensure effective heat transfer onto the salt mix underneath.

Carbofrax® domes function as muffles with excellent thermal conductivity and high-temperature chemical resistance, enabling long operational runs.

Refrax® 20 nitride bonded SiC bricks are ideally suited for use in the reaction tank, with cast Refrax® cast nitride bonded SiC providing outstanding chemical resistance to the spout blocks and rabble blades.

Can Saint-Gobain Performance Ceramics & Refractories provide flexible shape designs for different reactors?

Saint-Gobain Performance Ceramics & Refractories‘ high purity alumina and mullite dense insulating bricks, and its oxide bonded silicon carbide products are ideal for use in the fertilizer industry.

Saint-Gobain Performance Ceramics & Refractories works in partnership with major engineering companies in reactor design; leveraging this cooperation to provide materials with exceptional chemical, wear and thermal shock resistance, ultimately contributing to longer equipment service lives.

These engineering and production capabilities also enable flexible design services able to accommodate the most challenging refractory shapes for a wide range of reactor types.

How does Saint-Gobain Performance Ceramics & Refractories ensure its refractory linings meet the most severe application requirements?

Saint-Gobain Performance Ceramics & Refractories integrates its product portfolio, petrochemical process knowledge and refractory systems engineering skills with a number of key partners in the Saint-Gobain Group of companies. This combined experience and expertise ensures that all the company’s products can confidently meet requirements around corrosion, erosion, temperature resistance, pressure capability and service lives.

What experience does Saint-Gobain Performance Ceramics & Refractories offer in the field of petrochemical applications?

Saint-Gobain Performance Ceramics & Refractories has supplied refractories to the petrochemical industry for more than 60 years. The company’s extensive range of chromia, alumina-chromia, alumina, zirconia and silicon carbide products are routinely employed in processes such as gasification, reforming and refining, carbon black production, chemical production and nuclear energy applications. This wide range of products is provided in conjunction with diverse field experience, engineering and design capabilities; enabling the development of unique refractory solutions for customers worldwide.

Key benefits of refractory solutions from Saint-Gobain Performance Ceramics & Refractories include:

- Efficient containment of hot and/or corrosive gases, liquids, or solids

- Excellent thermal insulation

- Increased process availability due to increased outage intervals

- Efficient material stock management

- Experienced engineers with knowledge of hydrocarbon processing applications

- State-of-the-art CAD and Finite Element Modeling packages

- Mechanical and thermomechanical stress resistance

- Reliable performance throughout the equipment’s service life.

Related Product

Hexoloy SE Sintered Silicon Carbide Tubes and SA Tube Sheets

Discover Saint-Gobain Performance Ceramics & Refractories’ range of silicon carbide products for shell and tube heat exchangers.

Related Equipment

Secondary Reformers

Discover Saint-Gobain Performance Ceramics & Refractories’ range of solutions for secondary reformers.