Steel Wire Coating

Steel wire coating utilizes molten hot zinc to coat strands of wire in a continuous fashion. The bath of molten zinc is heated using silicon carbide single ended immersion tubes.

A typical zinc bath will contain between 10 to 20 immersion tubes. The zinc pot consumes a significant amount of energy and generates carbon and nitrogen oxide emissions.

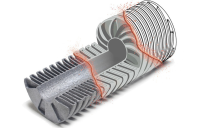

The immersion tube's energy usage, emissions and thermal performance can be improved through the use of high surface area heat exchangers such as HeatCor™ and radiant tube inserts such as SpyroCor™.

Related Products

Ceramic Radiant Tube

Discover Saint-Gobain Performance Ceramics & Refractories’ extensive range of solutions for high temperature heat treatment applications.

SpyroCor and NOxBuster Radiant Tube Insert

Discover Saint-Gobain Performance Ceramics & Refractories’ range of radiant tube inserts – ideal for improving efficiency in the furnace chamber.

HeatCor and Silit Recuperators

Discover Saint-Gobain Performance Ceramics & Refractories’ range of recuperators for integration into burner systems.

PyroCor and Silit Flame Tubes

Discover Saint-Gobain Performance Ceramics & Refractories’ range of flame tubes and diffusers – ideal for guiding the flow of combustion.

Amasic-3D Burner Nozzles

Discover Saint-Gobain Performance Ceramics & Refractories’ range of burner nozzles – ideal for guiding the flow of combustion.

Related Content

Single Ended Radiant Tubes

Discover Saint-Gobain Performance Ceramics & Refractories’ extensive range of solutions for high temperature heat treatment applications.

U-TUBE

Discover Saint-Gobain Performance Ceramics & Refractories’ solutions for high temperature heat treatment applications in U-tube combustion systems.

W-TUBE

Discover Saint-Gobain Performance Ceramics & Refractories’ solutions for high temperature heat treatment applications in W-tube combustion systems.

Total Burner Solution for Energy Efficiency and Carbon Reduction

Discover Saint-Gobain Performance Ceramics & Refractories’ extensive range of total burner solutions for industrial heating applications.