Automotive and Electric Vehicles

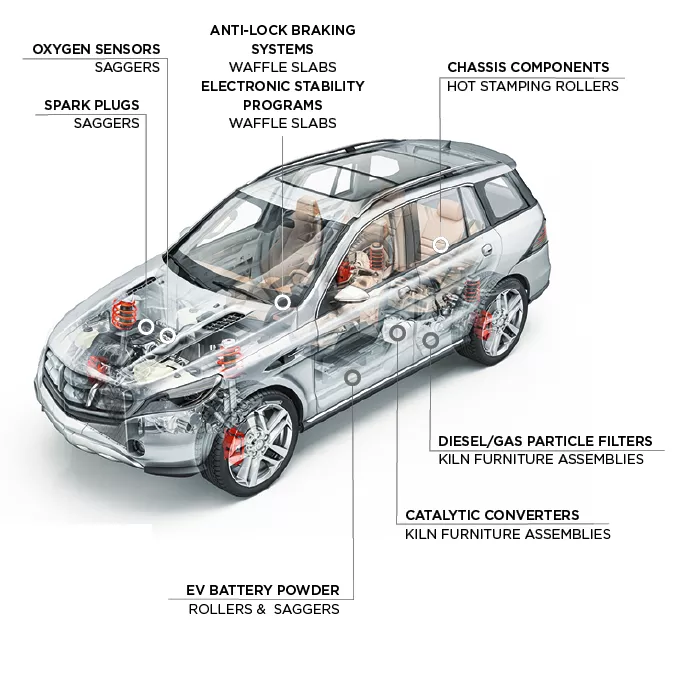

Sustainable, Adaptable Refractory Solutions for the Automotive Industry

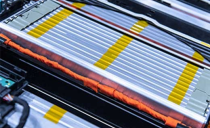

Electric Vehicles

We offer a range of solutions for the electric vehicle (EV) industry and deliver products for the thermal processing of lithium battery powder and the production of specialized metal components; sustainable and long-lasting rollers and saggers provide excellent resistance against product contamination and pollution.

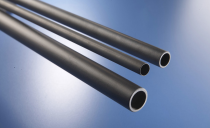

Rollers for CAM production

Saint-Gobain plays a key role in the EV battery supply chain. We support battery manufacturers and producers of cathode active material (CAM) powder for electric vehicles, whether NMC, LFP, NCA, or other specialized formulations. The selection and optimized production of the most appropriate cathode active materials increases the performance and structure of batteries, extends service life, and improves safety levels. Leading industry players produce CAM powder in specialized high-temperature furnaces in a challenging, and sometimes corrosive, environment. This is where Saint-Gobain brings value to the process.

Our silicon carbide (SiC) ceramic rollers are ideal for use in furnaces where production rates, product quality, and minimized downtime/interruptions are crucial. Using advanced silicon materials enables the reliable production of the most effective and dependable products necessary for lithium-ion car batteries.

In short, Saint-Gobain develops products that bring maximized value to the components that car battery manufacturers require. As such, we must provide these at the highest quality.

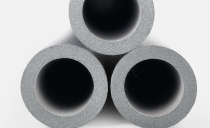

Saggers for CAM production

Additionally, we are involved in sagger production for CAM powder sintering and processing. Our ceramic saggers protect CAM powders from contamination, which would otherwise impact the performance and safety final li-ion batteries, while improving heat transfer uniformity (final product consistency). Our unique, drop-in design supports increased throughput while reducing early failure due to thermal shock, increasing the average lifetime of the sagger. Ultimately, use of Saint-Gobain saggers result in increased CAM product quality, consistency, and throughput while reducing the overall energy use of the process and ceramic waste streams through increased cycle life.

Hot Forming Rollers

Our specialty advanced ceramic products and advanced silicon carbide materials are seen as the industry benchmark in solving a range of processing challenges from chemical processing to heat exchangers, sandblasting to semiconductor wafer processing. For the automotive industry, we leverage our vast ceramic materials portfolio to manufacture the rollers used inside furnaces and kilns to provide outstanding shape stability, thermal conductivity, thermal shock resistance, defined flatness, and surface finish.

We maximize the sustainability of our products through an optional proprietary retake and refurbishment process, reducing the cost to the user and minimizing the raw ceramic material required to support production. These are all features that make this material an ideal solution for the automotive market.

FAQ

What are the advantages of employing LO-MASS® kiln furniture in DPF, filter and substrate manufacturing?

Employing LO-MASS® components in the firing of diesel particulate filters (DPF) and automotive substrates can significantly reduce costs. LO-MASS® components increase productivity for DPF, filters and substrate manufacturing while reducing energy consumption; while the production of thin, lightweight plates and profiles provides more efficient utilization of the furnace and maximum cost benefit per kiln unit.

Its high mechanical strength at high temperature allows a high load of filters per plate, as well as the potential to design an energy saving system.

In addition to offering increased strength and output, LO-MASS® components provide the sustainability every company strives for. Saint-Gobain Performance Ceramics & Refractories is the industry leader in the development of silicon carbide materials, which are resistant to oxidation at higher temperatures.

Kiln furniture for use in the manufacture of DPF, filters and substrates is primarily based on Advancer®, N-Durance® or Hexoloy® materials. These products offer excellent performance and chemical resistance to the fired product.

Leveraging the power of the proprietary KilnWorks® custom analysis software, Saint-Gobain Performance Ceramics & Refractories’ engineers can design and develop kiln furniture ideal for the customer’s specific application.

When given a choice between traditional or LO-MASS® kiln furniture, LO-MASS® silicon carbide components are the obvious choice.

Documents

Related Product

Silit® Rollers

Discover Saint-Gobain Performance Ceramics & Refractories’ range of Silit® silicon infiltrated rollers - optimal properties in a wide range of firing...

Hexoloy® Rollers

Discover Saint-Gobain Performance Ceramics & Refractories’ range of Hexoloy® silicon carbide rollers – ideal for use in high-temperature roller hearth...

Crystar® Rollers

Discover Saint-Gobain Performance Ceramics & Refractories’ range of Crystar® recrystallized silicon carbide rollers – ideal for use in high-temperature...

DuraFORM® Rollers

Découvrez les rouleaux en carbure de silicium DuraFORM® de Saint-Gobain Performance Ceramics & Refractories, idéaux pour les fours à sole roulante à haute...

LO-MASS® Kiln Furniture

Discover Saint-Gobain Performance Ceramics & Refractories’ comprehensive range of solutions and materials for kilns and furnaces, including kiln furniture...

Saggers

Discover Saint-Gobain Performance Ceramics & Refractories’ range of saggers - design and material options for the most demanding temperatures and firing...

Related Content

Hot Stamping

Discover Saint-Gobain Performance Ceramics & Refractories’ range of high-performance ceramic rollers – ideal for use in all roller hearth kiln zones and...

Diesel Particle Filters and Gas Particle Filters

Discover Saint-Gobain Performance Ceramics & Refractories’ range of LO-MASS® kiln furniture - excellent strength, shape and assembly stability for large...

Lithium-Ion Battery Cathode Powders

Discover Saint-Gobain Performance Ceramics & Refractories’ range of high-strength silicon carbide rollers – suitable for roller hearth kilns used to...

Systems for Kilns & Furnaces

Discover Saint-Gobain Performance Ceramics & Refractories’ comprehensive range of ceramic products and solutions - designed, developed, and manufactured...